Creating the wayfinding signage for Manchester’s luxury skyline.

Project: Deansgate Square

Location: Manchester

Sector: Residential

Client: Renaker

Partners: F.r.a. Creative

Photography: TBC

Deansgate Square: luxury skyscrapers made for Manchester’s elite

Completed in 2020, Deansgate Square is a luxury residential skyscraper cluster located in Manchester.

With stunning views, architecture and interiors, as well as a host of premium amenities, it offers residents a truly sensational home, lifestyle and neighbourhood.

Working with F.r.a. Creative, a leading wayfinding design consultancy

After a rigorous tender process, we were delighted that F.r.a. Creative, contracting for Renaker, selected us to build and install their wayfinding design for the whole development.

As Deansgate Square was such an ambitious luxury build, understandably F.r.a’s tender proposal was extremely thorough. Their specification documentation stipulated their expectations for the whole project, outlining its exact requirements for design and material, to construction and installation.

We’re pleased to say that we both consulted on, and met, all of this brief. For some insight of how we dealt with some of the specification’s most significant challenges, please see the Deansgate Square: Spec challenges below.

Beautifully sophisticated art deco inspired brass signage

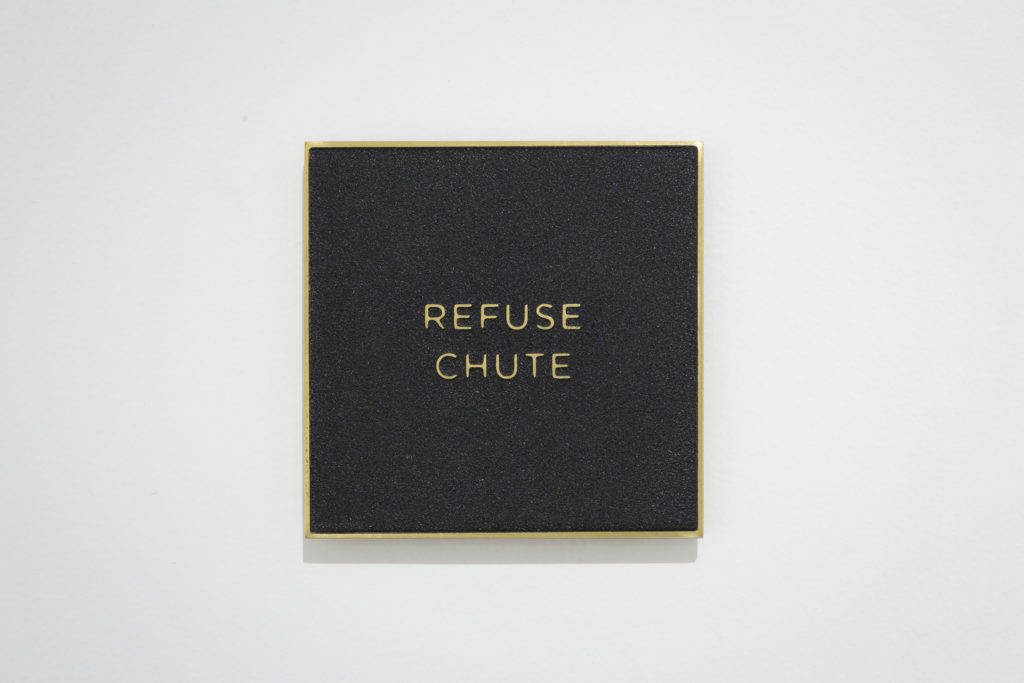

As Deansgate Square’s dramatic skyscrapers’ design were Manhattan-inspired, F.r.a’s wayfinding signage very much followed suit; elegant art-deco styling and typography set in various expressions of brass. As brass signage specialists, this was a dream project to work on.

Therefore, the complete signage suite of around 4000 signs used a host of specialist brass signage techniques. This included customised chemical etching, laser cutting, hand-finishing, and gold leafing (delivered by our traditional sign writer with over 50 years expertise).

Lead by F.r.a’s highly creative designs, these techniques were applied across a range of signage formats, both high impact, such as totems and oversized text, and nuanced, such as textured finished door numbers.

A satisfied client, and continued business partnership

Overall, we’re proud to have delivered Deansgate Square’s large signage suite to F.r.a’s standards, on time and in budget.

We continue to have a close business partnership the F.r.a, and are currently working on several significant projects with them.

Deansgate Square: Spec challenges

In this section, we provide insight of how we dealt with some of this project spec’s most significant challenges.

Consultation

Upon reviewing F.r.a.’s spec, we identified that many aspects of their design proposal raised significant build challenges.

For their floor identification signage, F.r.a. had specified it to be built from 10mm brass. As a brass signage specialist, we recognised that not only would this be very expensive, when laser cut its near impossible to get a smooth finish, posing a health risk for residents.

In light of this, we advised to create this signage from 6mm brass with hand-polished edges.

In turn, for their reverse-etched signage, F.r.a want a unique asphalt-styled textured finish. As a leader in chemically etched signage, we advised that there was no standard manufacturing process for this finish.

To deliver this unique asphalt-styled textured finish for F.k.a., we created it with our supplier. We then mechanised the process to be able to roll it out on a large scale.

Quality Assurance

As F.r.a. work with leading building contractors, to ensure quality control their specification requirements are very demanding, stipulating high standards across every aspect of the signage project.

To ensure that our signage met F.r.a’s meticulous requirements, we followed a rigorous quality assurance process.

Before constructing any signage, we:

used a professional art worker to visualise every one of F.r.a.’s sign designs

prototyped a range of F.r.a.’s more challenging sign finish requests

welcomed Fr.a. to visit the workshop to review the signs

When installing the signage, we:

used software called Sightworx to send F.r.a. monthly progress reports

conducted an on-site review

Procurement

As F.r.a. work with leading building contractors, to ensure quality control their specification requirements are very demanding, stipulating high standards across every aspect of the signage project.

From reviewing F.r.a’s brief, it was clear that their design proposal required a huge quantity of brass. Due to global trade issues caused by Brexit and Covid-19, brass is currently very expensive and difficult to source.

Thanks to our very strong network of suppliers, we were able to procure the needed brass from a mill based in Germany. Due to expediting and lead time issues, this was complex and time-consuming process.

used software called Sightworx to send F.r.a. monthly progress reports

conducted an on-site review

Timescale

Delivery and Installation

In order to maximise installation efficiency, we delivered each signage set to the exact installation location. In turn, to keep a orderly site, were exacting in how we installed, making sure that once done the site was neat, tidy, and met safety regulation.